Household appliances

Plastics are widely used in household appliances, serving as both the "outer shell" and the "internal framework." As appliances move toward greater intelligence and high-end development, plastics continue to advance in environmental sustainability, lightweight design, and functional integration.

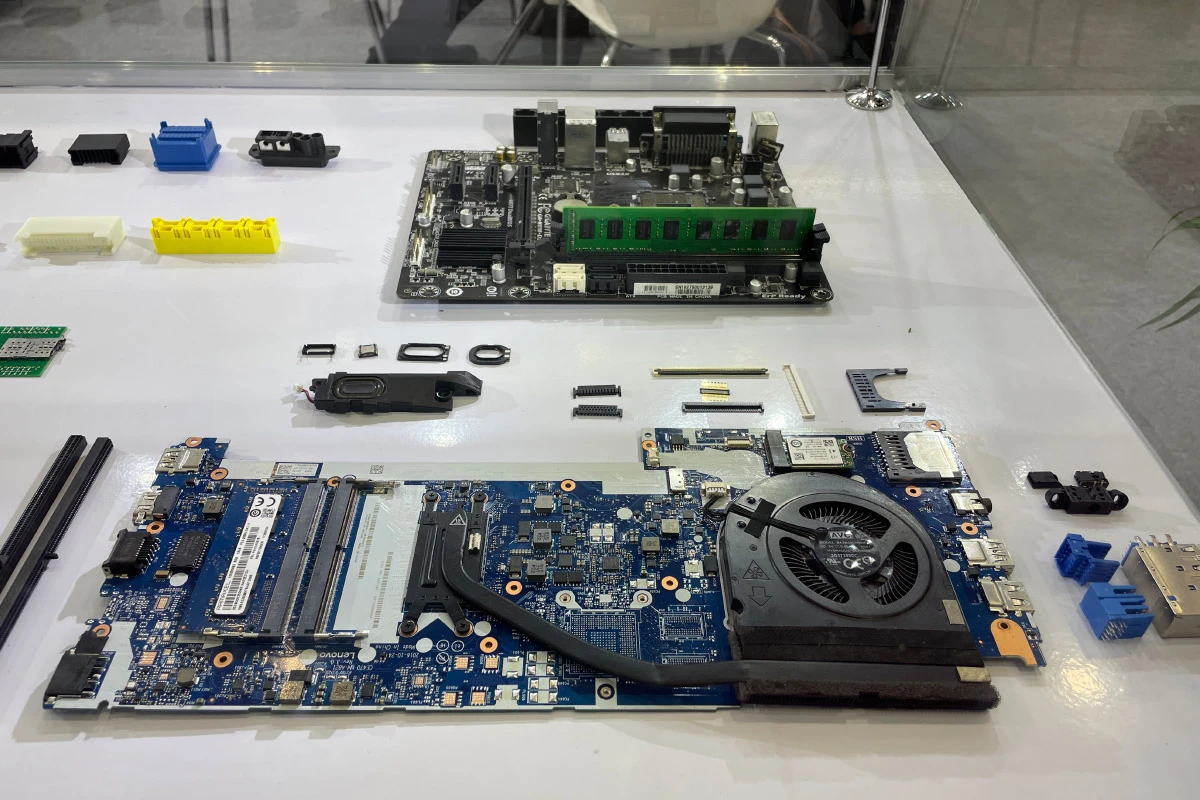

Electronic products

Plastics provide electronic products with lightweight, attractive, and durable protection. Thanks to their excellent insulating properties and moldability, they are widely used in components such as circuit board substrates, sockets, and connectors, ensuring the safety and stability of electronic components.

Electrical and electronic

Thanks to their excellent insulation, heat resistance, and processability, plastics are widely used in key components such as switches, sockets, power adapters, motor housings, connectors, and relays, ensuring the safety and reliability of electrical equipment.

Auto parts

With the development of new energy vehicles and smart cars, the innovative applications of plastics in lightweight design, electrical insulation, thermal conductivity, and environmental recyclability are continuously driving the automotive industry toward greater efficiency and sustainability.

Consumer goods

Thanks to their antibacterial, flame-retardant, high-temperature-resistant, and recyclable properties, plastics have permeated every aspect of home life, appearing in items such as storage boxes, water cups, and baby bottles. They make consumer products lighter, more practical, and more in tune with modern lifestyles.

Children's toys

Thanks to its lightweight, safety, ease of processing, and vibrant colors, plastic is widely used in a variety of products such as building blocks, models, and baby walkers. Its moldability and ease of coloring allow for more diverse toy designs and richer colors, inspiring children's creativity and imagination.

Communication

With the development of 5G and the Internet of Things, plastics not only contribute to the lightweighting and structural optimization of communication equipment but also continue to innovate in thermal conductivity, shielding, electromagnetic compatibility, and environmental recyclability, becoming an indispensable material support for modern communication technology.

Food containers

Through non-toxic, odorless modifications that meet food contact safety standards, plastic containers ensure the hygiene and safety of food. At the same time, degradable plastics, recyclable materials, and bio-based alternatives are increasingly being used in food packaging, enabling plastic food containers to strike a balance between convenience and sustainability.

Paints and inks

With the growing demand for environmental protection and sustainability, water-based resins, biodegradable resins, and low-VOC materials are gradually replacing traditional solvent-based resins, driving inks and paints toward a greener and more eco-friendly direction.

Safety and protection

Compared with traditional metal and glass, plastic protective equipment is lighter, more comfortable to wear, and easier to mass-produce. UV-resistant, antibacterial, biodegradable, and high-performance composite plastics make safety protection products not only more effective in ensuring personal safety but also more environmentally friendly and user-friendly.

Aerospace applications

Compared with traditional metals, plastics significantly reduce aircraft weight, improving fuel efficiency and range. At the same time, advanced engineering plastics and composite materials are driving continuous innovation in aircraft design flexibility, energy efficiency, environmental sustainability, and long-term durability.

Fitness equipment

Plastics allow for diverse designs and color combinations, giving fitness equipment a more stylish and personalized appearance. The use of recyclable plastics, eco-friendly TPU, and high-performance composite materials in fitness equipment achieves a balance between functionality and sustainability.